CTK Acoustics 2.0 Box – damping mat 16 pcs/2.96 m2

239,00 zloty

CTK Acoustics 2.0 Box – damping mat 16 pcs/2.96 m2

239,00 zloty

- Description

- Additional information

- Opinions (0)

Description

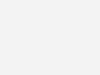

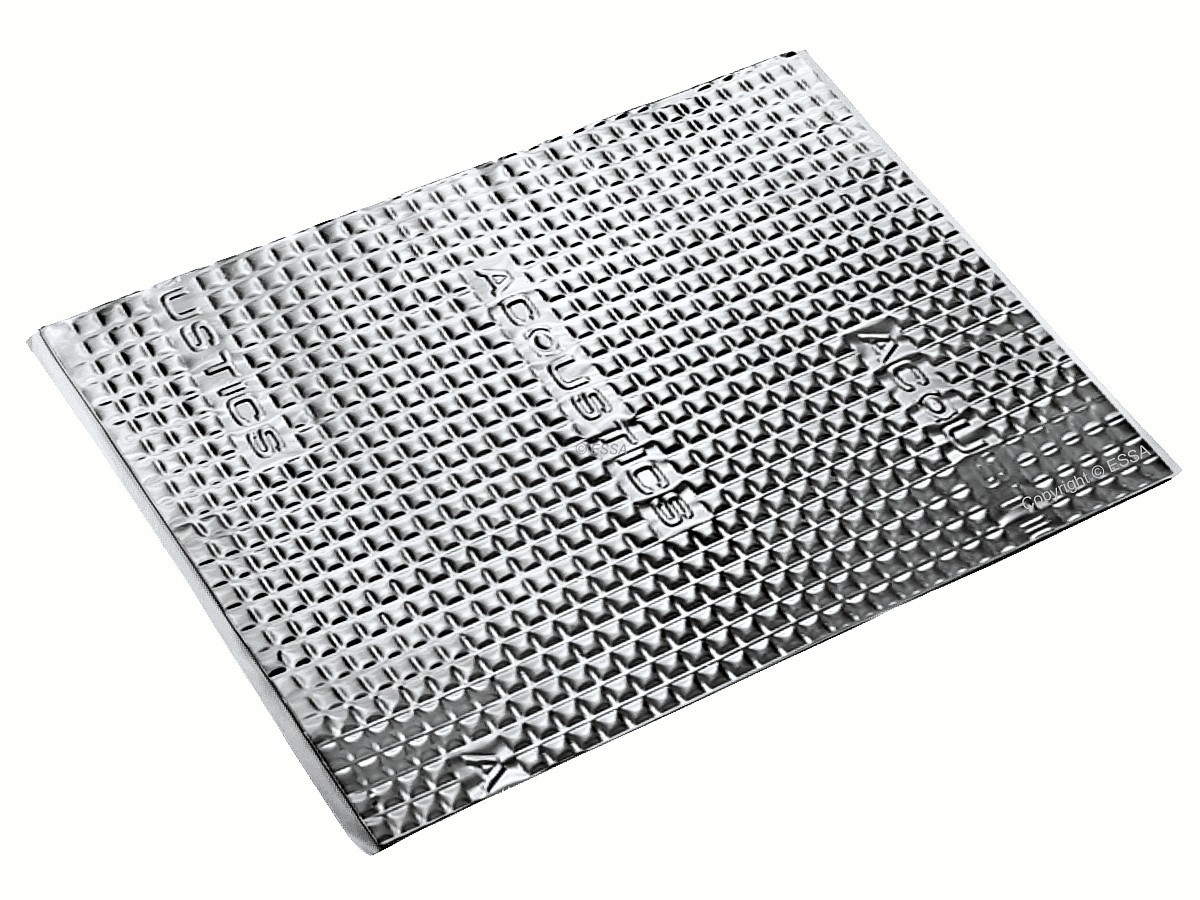

Butyl mat 2.0mm with 60µm aluminum foil for soundproofing vehicle bodies, machines, household appliances – 16 pcs. 37x50mm (2.96m2), MLF=0.24

CTK Acoustics 2.0 Box:

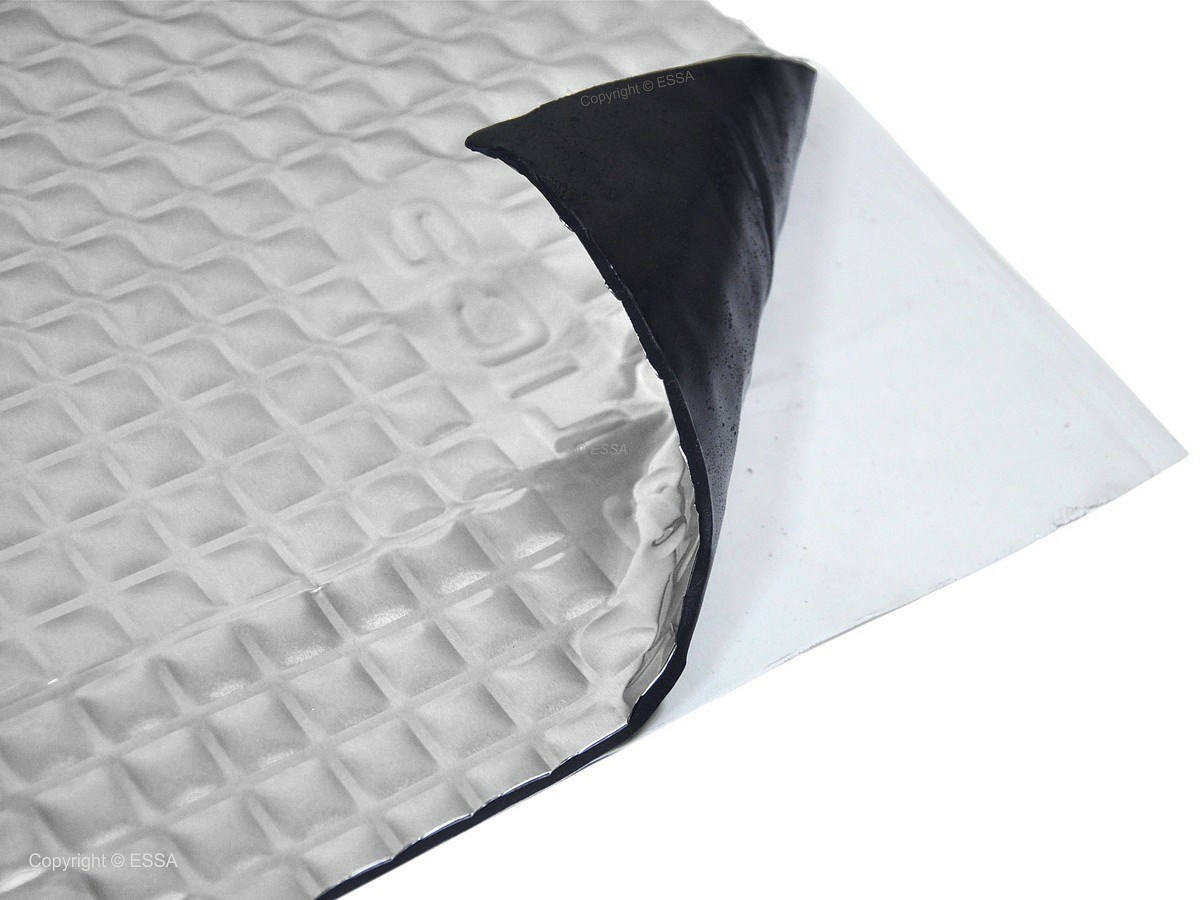

An affordable, highly flexible, self-adhesive aluminum-butyl mat for cost-effective vibration and acoustic resonance damping in car bodywork and upholstery, yachts, machinery, industrial equipment, computer housings, consumer electronics, and household appliances. Excellent value for money. Price per pack: 16 sheets measuring 370 x 500 mm (2.96 m²), mat thickness 2.0 mm, aluminum foil thickness 0.06 mm (60 microns).

CTK Acoustics is a versatile, two-layer, affordable anti-vibration material designed for vibration reduction and basic noise reduction. The material is made as a flexible, self-adhesive mat with a butyl rubber-based damping layer. The outer layer is embossed with 60-micrometer (0.06 mm) thick aluminum foil, which provides mechanical reinforcement and protection for the butyl damping layer and further improves its acoustic properties. CTK Acoustics series soundproofing mats are primarily used for inexpensive, basic noise reduction and vibration and acoustic resonance reduction in vehicle body components (doors, roof, floor, trunk, engine cover, plastics, and upholstery). They can also be used indoors, for example, to dampen machinery, generators, computer equipment housings, air conditioning units, household appliances, and metal sinks, shower trays, and bathtubs. The product is non-toxic, waterproof, does not absorb moisture, and does not decompose under the influence of weather conditions. It has anti-corrosion and sealing properties. CTK Acoustics mats are also suitable for less advanced work aimed at improving the overall acoustics of a car's cabin, during the installation and use of car audio equipment, and for supplementing or renovating sound insulation after bodywork repairs.

To achieve maximum vibration dampening and the highest possible level of sound insulation, it is necessary to use technologically advanced professional or premium materials, which are characterized by significantly higher efficiency while being thinner and/or lighter.

BASIC PARAMETERS:

- total thickness: 2.0 mm +/- 0.2 mm

- aluminum foil thickness: 0.06 mm (60 µm)

- material: butyl rubber-based composite reinforced with embossed aluminum foil

- MLF (mechanical loss factor) – vibration damping efficiency (more = better): 0.24

- dimensions of 1 sheet: 370×500 mm

- area of 1 sheet: 0.185 m2

- quantity per package: 16 sheets / 2.96 m2

- weight: 10.56 kg/pack (3.57 kg/m2)

- recommended installation temperature: +10ºC to +30ºC

- application and operating temperature range: -40ºC to +120ºC

- a product with anti-corrosion and sealing properties, waterproof, does not contain bituminous admixtures (no tar or asphalt)

- non-toxic, non-flammable (self-extinguishing) product, does not emit unpleasant odors, can be used in the automotive industry and in closed rooms

- visual features: silver aluminum foil with rectangular embossing, embossed ACOUSTICS logo

- manufactured by CTK Ltd. in accordance with the quality management standards ISO 9001:2008, SIC.02.040.1344

- Application in the car: doors, roof, floor, trunk, engine cover, trunk lid, plastics, upholstery elements

- price per package – 16 sheets measuring 37×50 cm (2.96 m2)

CTK vibration dampening materials are non-toxic and safe to use, in accordance with European Union (EC) requirements. These products have a positive laboratory test report, accepted in EU countries, confirming compliance with the requirements of Regulation (EC) No. 1907/2006 of the European Parliament and of the Council of 18 December 2006 – REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

INSTALLATION

CTK Acoustics mats are self-adhesive, highly flexible, and easy to apply to surfaces of flat or complex shapes. They can be installed in a wide temperature range without the need for heating, but the highest operating comfort is achieved at ambient temperatures above +10ºC. The surface to be bonded must be dry, clean, and very well degreased. To maximize the damping properties, press the mat firmly after application, e.g., using a roller, to ensure it adheres completely to the entire surface of the substrate being damped, without creating air pockets. The self-adhesive butyl layer has self-vulcanizing properties, which, over time, further increases the material's adhesion to the substrate, creating a cohesive whole.

DAMPING EFFECTIVENESS:

When soundproofing a car, the desired effect is achieved by acoustically insulating its interior and, above all, by significantly reducing (damping) the amplitude of mechanical vibrations in the metal and plastic components of the car's body and cabin. To achieve this, flexible and slightly elastic materials (e.g., butyl rubber-based) are applied to the damped components. These materials suffer from significant mechanical energy losses due to internal friction. As a result, vibration energy is absorbed by the damping material and converted into heat. The ability of a given material to absorb mechanical vibration energy depends on many factors, including its design, chemical composition, weight, thickness, etc. This determines the mechanical loss factor (MLF), which is one of the most important parameters to consider when selecting vibration-reducing materials. This coefficient is expressed numerically in the range of 0.00–1.00 for a specific frequency and temperature (the higher the MLF value, the greater the material's ability to dampen vibrations). To noticeably reduce noise and vibration inside a vehicle, materials with the highest possible mechanical loss factor should be selected. When damping car body components, the lowest possible weight of the damping material is also important, which often does not translate into maximum damping effectiveness. Therefore, the best compromise should be sought between a high mechanical loss factor (MLF) value, low material weight, and an adequate price. In the car audio industry, when damping car doors where speakers will be installed, it is common practice to "close" the factory-made holes by sealing them with damping mats (creating a sealed speaker chamber). In these places, the best solution is to use mats with a high MLF factor, moderate weight and a thicker aluminum foil (100 micrometers or more), which provides greater stiffness and stability of the surface over the sealed technological holes.

HOW TO EFFECTIVELY SILENCE A CAR?

The highest level of soundproofing a vehicle's interior can only be achieved by comprehensive soundproofing (damping, acoustic isolation, and soundproofing) of all key body and interior components. Layering these components (where possible and space permits) with three different types of the most effective, top-quality materials, each with different acoustic properties, operating in a different frequency range, and fulfilling a different role. These are:

- layer 1 – highly effective anti-vibration materials that dampen vibrations and resonances of body elements and additionally isolate the interior from external noise, which are high-quality mats based on butyl, aluminum and polymers with the highest possible MLF value (e.g. CTK Dominator, CTK Premium, CTK Standard Professional damping mats),

- layer 2 – foam insulation – sound barriers with a closed-cell structure, blocking the passage of road noise into the cabin and additionally thermally insulating the interior against excessive heating and rapid cooling (e.g. CTK Elastic, CTK Elastic F rubber foams, CTK TempoFix polyethylene foams),

- Layer 2/3 – soft, porous sound-absorbing materials with an open and/or partially closed cell structure, which, in addition to their sound-absorbing properties, also act as shock-absorbing spacers and dampen the resonance of plastic upholstery elements, reducing the creaking and squeaking of these elements (e.g. CTK SilenceFix and CTK WaveFix polyurethane sound-absorbing foams, CTK CaiMat non-woven fabric-based sound-absorbing mats). For the best road noise reduction effect, it is also recommended to install the CTK Block Pro acoustic membrane as the last third layer on the lower horizontal body elements.

Additional information

| Libra | 11.36 kg |

|---|---|

| Status | <font color=red>available from 7 to 14 days</font> |

| Manufacturer's index | CT-ACO20P |

Opinions

There are no reviews for this product yet.